Uncovering the results of lightweight insulation

Weight vs Insulation - why not all boats are well insulated

Ships navigate remote, stormy seas, and face extreme temperatures, all while passengers and crew are confined to compact spaces. Protecting the crew against the heat and cold is essential to ensure the ship remains habitable, but using insulation on board a ship presents a unique challenge. One of the critical factors is the trade-off between weight and insulation performance. Traditional insulation materials, like thick glass wool, are often too heavy for marine applications, increasing the vessel's weight and affecting the ships performance. Conversely, using less insulation can lead to higher energy costs for heating or cooling the vessel and inadequate noise reduction.

As a consequence many ships could have better insulation values. Many boats are not well insulated - or at all - which means they rely on using more energy (mostly diesel) for heating and cooling. To overcome this problem, the ideal solution lies in finding materials that offer the perfect balance between weight and insulation efficiency. One innovative company has found a solution to this problem. Pyrotek is a globally recognized leader in noise control and insulation solutions. The company is at the forefront of development and manufacturing of innovative insulation materials tailored for the maritime industry. Their insulation solutions utilise advanced materials and engineering techniques to provide superior noise reduction and thermal regulation, while minimising weight.

To understand how Pyrotek's acoustic and thermal solutions work, we followed a team of renowned industry experts, including Dykstra Naval Architects, Vripack Yacht Design, and Vitters Shipyard, who are working on a project to create a ship that does not use fossil fuels during its operations, called Zero. A pivotal aspect of this ship is energy efficiency, which is why insulation is so important. The ship naturally needs to conserve energy as much as possible, not being able to simply rely on using more fuel for heating or cooling, requiring materials that are not only effective but also lightweight.

How insulation improves energy efficiency

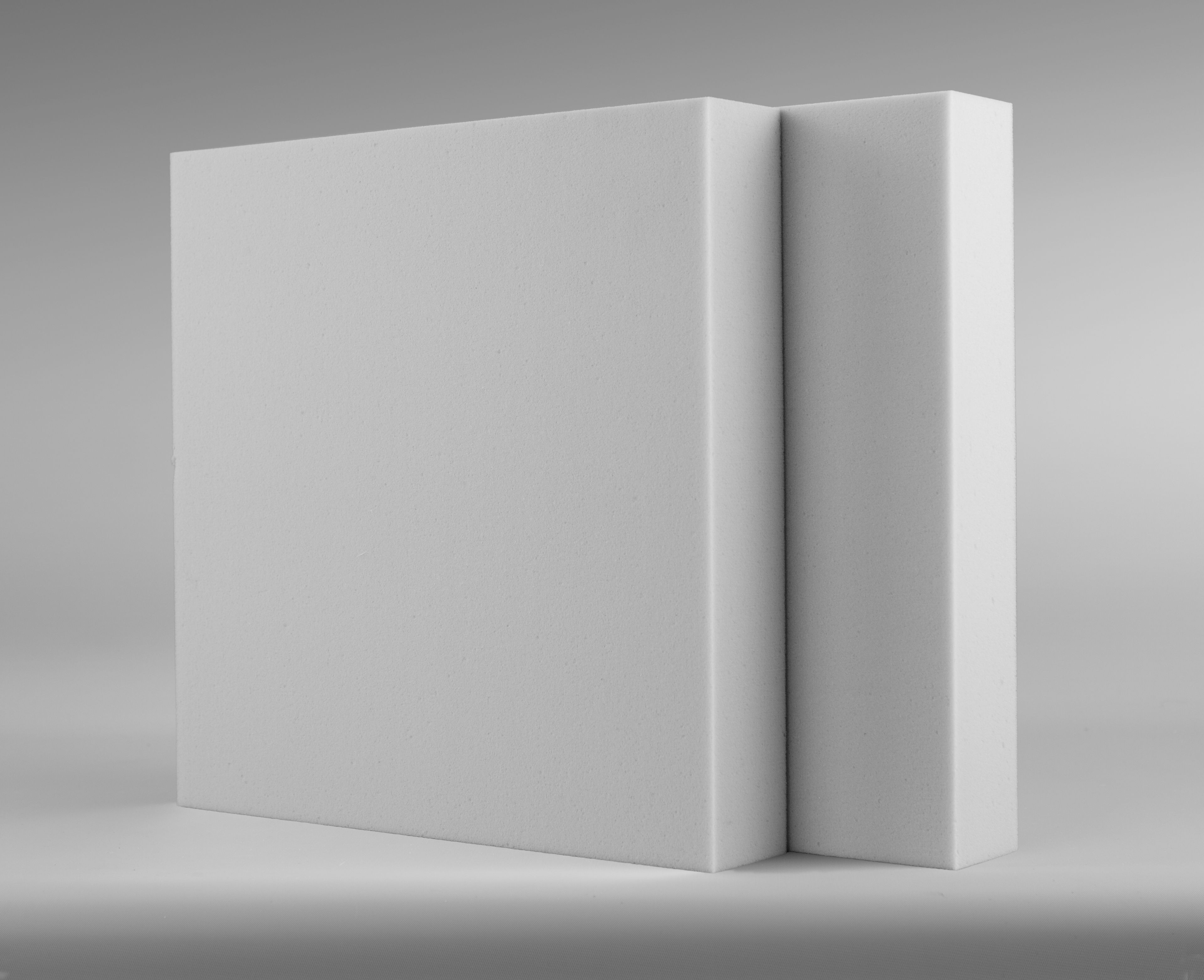

Sorbermel and Sorbermel AGC are exceptional in this regard, providing high noise absorption and insulation capabilities without adding unnecessary weight. An impressive 2.200 m2 of Sorbermel is to be installed throughout the vessel to address noise mitigation and thermal insulation, yet at a remarkable weight of only 9 kg per cubic metre. For comparison, traditional insulation materials used in other marine projects provide good insulation but also weigh much more. Standard thermal and acoustic insulation in glass wool can vary from 24-36 kg/m3, and polyurethane foams, 22-30 kg/m3. So melamine, the material used in Sorbermel, can be up to 70% lighter than conventional insulation systems. Foundation Zero is estimating a factor of 2,6 better insulation values compared with glass wool and rock wool for the same weight budget.

It is especially these excellent thermal insulation properties which make this material so interesting for maritime applications. The open-cell structure of melamine foam consists of numerous small interconnected pores. Air, being a poor conductor of heat, is trapped in these pores, thereby reducing heat transfer. The trapped air acts as an insulating barrier, slowing down the movement of heat through the material, illustrated by Sorbermel’s thermal conductivity ranging from 0.035 to 0.036 W/mK between 10 °C and 20 °C.

The material is able to provide these insulating properties even at high temperatures. Its thermal stability and ability to resist hydrolysis ensures that it does not degrade or lose its effectiveness as an insulator over time when exposed to varying temperatures, which is essential for marine environments where temperature fluctuations are common. By providing effective noise control and thermal insulation in a single material, the product streamlines the insulation process, reducing complexity and weight while improving overall vessel performance and energy efficiency.

Both products also deliver excellent noise absorption thanks to a three-dimensional network structure of slender filaments. This highly porous, open-cell structure enhances sound absorption by trapping and consequently dissipating sound waves within this delicate system, preventing them from reflecting back as reverberation. This structure provides absorption across a broad range of frequencies.

The Impact

Pyrotek’s thermal solutions are integral to making the ship Zero as energy efficient as possible. The installation of the innovative insulation materials contribute to the vessel’s efficiency, with the lightweight nature of these materials being a crucial benefit. Lightweight materials like this could contribute to making the maritime industry more energy efficient as they solve a core problem of having to balance weight and insulation effectiveness.