High Tech Telltales

Most people wouldn’t imagine that a simple 10 cm long piece of string could significantly influence the speed of an entire sailing boat. But if you look more closely at the sail cloth of everything from a small dinghy to a carbon fibre racing yacht you will find many of these small pieces of string attached seemingly at random. Contrary to their insignificant appearance these “telltales” are still the primary mechanism for sailors to read how well their sails are positioned relative to the wind, and therefore how efficiently they are operating.

But what if technology could supplement, or even replace, this age old method of sail reading to increase performance?

Of course the telltales themselves are only one part of the challenge. On every professional racing boat a number of the athletes hold the title of “Trimmer.” Their job is to observe the telltales and, depending on their behavior, to grind a winch which controls the tension and shape of the sail in order to achieve the fastest possible boat speed. This dance to get the sail shape just right under constantly changing conditions is a craft which involves a delicate balance of observation, winch grinding, and communication between trimmers and the captain.

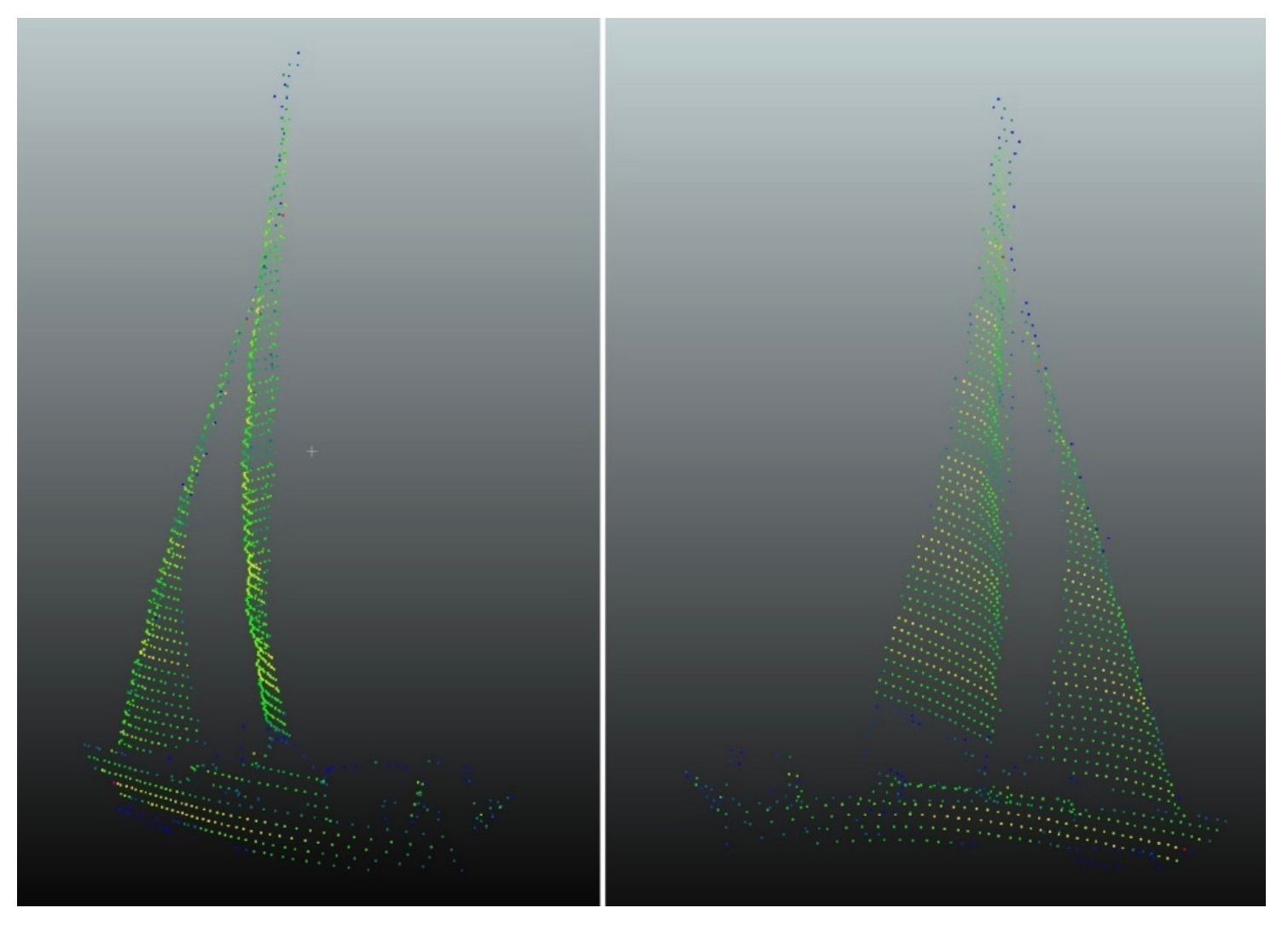

But advancements in LiDAR and photogrammetry are leading some to bet that this dance between sail tension, steering direction and boat speed could be reduced to a hard science. This is primarily because these technologies might unlock the ability to precisely determine the 3D shape of the sail in real time. And if this data is combined with other data points it could lead to a new era of precision sail trimming.

In fact, in wind tunnels this tech is already used to do exactly that. LiDAR scanners document the 3D shape of sails being tested under laboratory conditions to help designers make calculated improvements.

And America's Cup racing boats are rumored to be experimenting with LiDAR technology onboard already. But the practice is shrouded in secrecy so it’s unclear whether this is merely for post-race analysis of the sail shape or for real time trimming assistance.

In other words it seems just a matter of time until this technology makes the leap from the laboratory, to the instrument dashboards of sailing yachts.

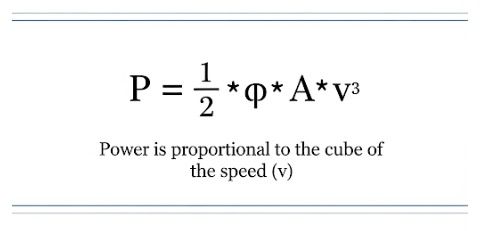

Speed equals power

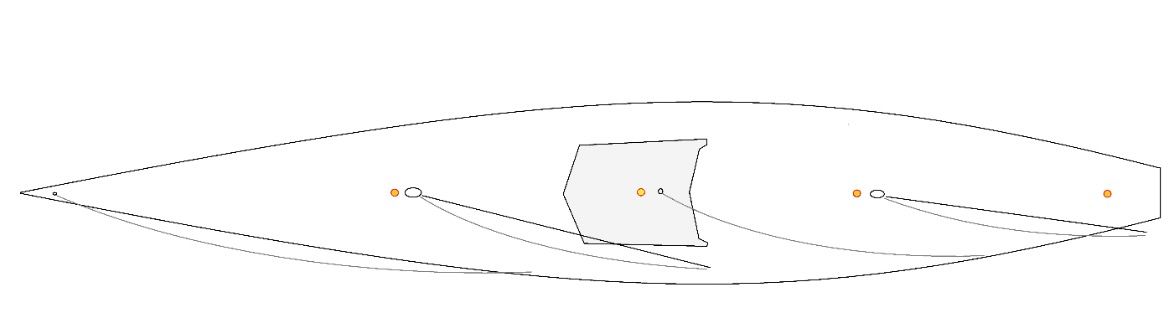

This recent report, commissioned by Sailing Yacht Zero and compiled by Ardis Bollweg from Geodelta discusses the suitability of LiDAR and photogrammetry for determining 3D sail shape in real time to inform sail trim. Unlike a racing yacht though, the 69 m long Sailing Yacht Zero is not looking for performance just in terms of speed, but rather in terms of power generation.

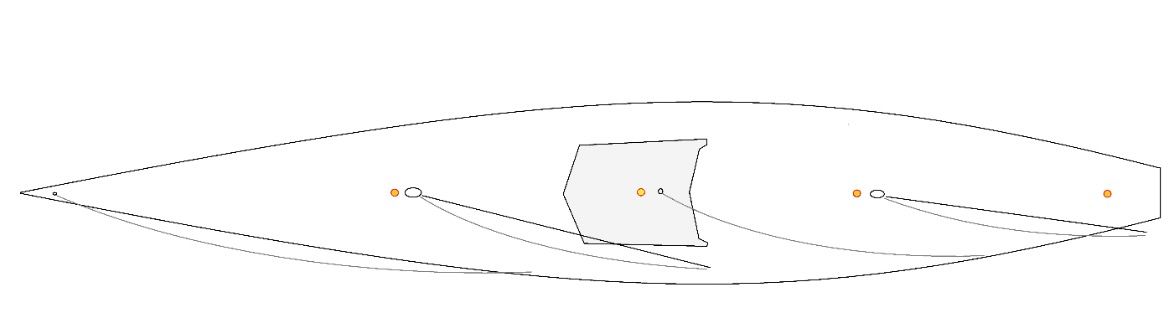

Sailing Yacht Zero is the first yacht of its size being built with rotating thruster pods capable of facing forward and generating up to 250 kW of power while under sail. The power is used to charge its 5 MWh lithium ion battery bank, and seeing as there are no fossil fuels onboard at all the ability to charge this battery bank while at sea is crucial to its operation.

You might think that such tiny changes in sail shape and performance gains would only be practical at the professional racing level. Until you consider that the energy which can be harvested by hydrogeneration is a function of the sailing speed, cubed. Which means a 10 % increase in speed could mean a 33 % increase in power generated, which is a big deal for Sailing Yacht Zero. But it could also be a big deal for the shipping industry with the recent rise in interest around sail assisted cargo ships.

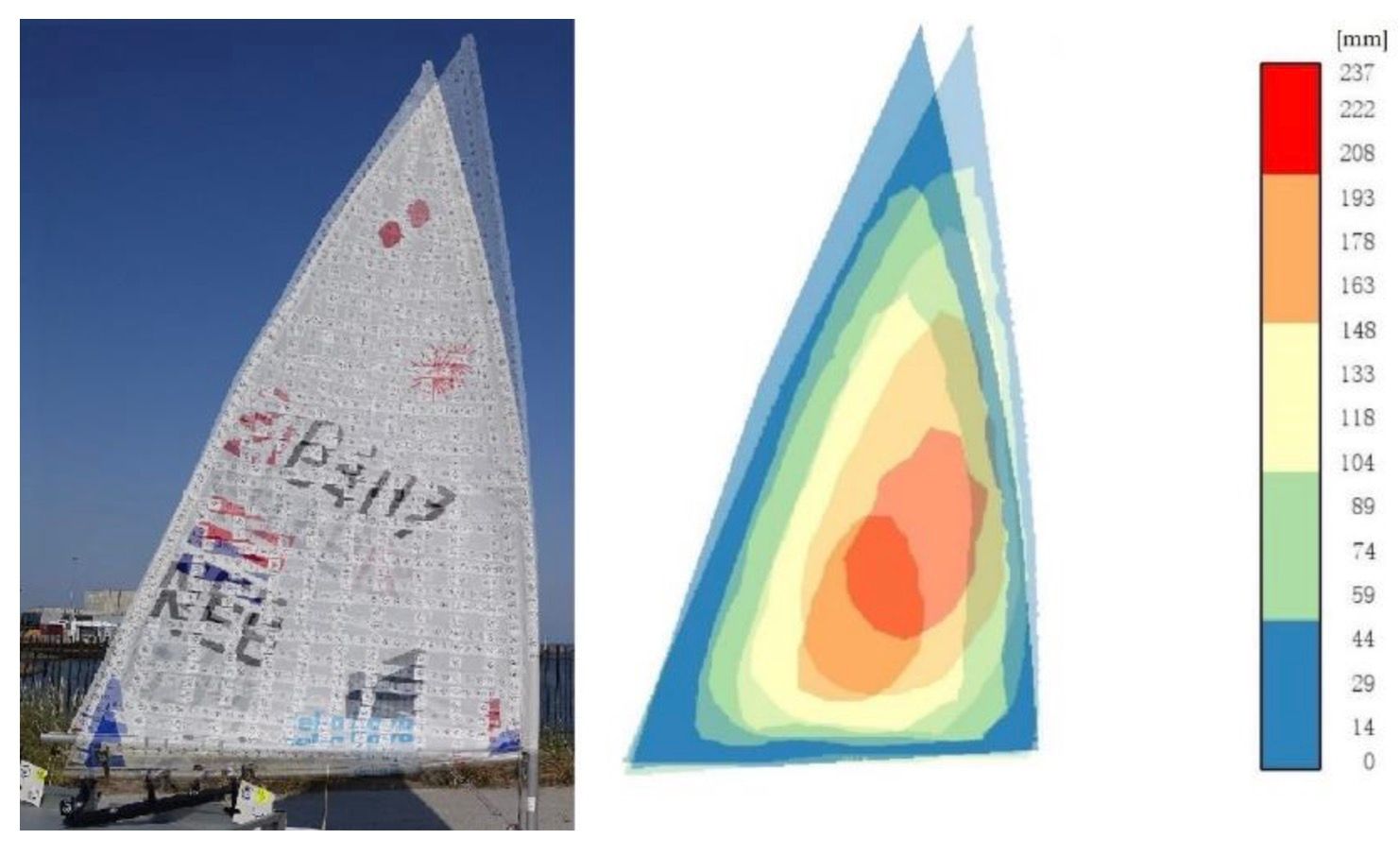

Geodelta specialises in quality control of (mostly airborne based) technical measurements but in 2022 Bollweg, an avid sailor herself, helped develop a prototype 2 camera system to determine 3D sail shape which they tested on a small dinghy. So we sat down with her to chat about the potential of these technologies, and how her sailing hobby led her to this idea.

"With airborne photogrammetry two overlapping images will provide information not only in two dimensions but also the height component.” explain Bollweg. “This is the same technique which allows you to see depth with your eyes. So if photogrammetry works from an airplane or drone to the surface, then it would technically be possible to make two images of a sailboat and measure the 3D sail shape.”

The big idea

There are three main hurdles which the technology will have to overcome to realise real world performance gains for Sailing Yacht Zero.

The first challenge is to get a real time read of the 3D shape of the sail under real world sailing conditions. But solving this problem alone won’t actually improve sailing performance at all. Professional sailors take years to learn exactly what adjustments to make based on a simple glance at the telltales. So it’s not about the sail shape itself. It’s about reading the sailshape to know what adjustments to make to better position the sail for more boat speed.

So challenge number two is the processing of this 3D sail shape data into real time meaningful information which can be presented to sailors to help them make quick decisions on sail trimming. But sailors don’t necessarily think of sails as 3D objects, and most of the terminology they currently use describes the shape of the back edge of the sail, not its shape in three dimensions.

“The next question was what information can we get out of the system to tell the sailor what to do. So to show a green dot when it's perfect or an orange dot you have to steer up or more tension on the sheet … that’s still a difficult problem,” notes Bollweg. “I think about it like wine tasting. You can taste wine, but you don't know how to pronounce what you taste. I think this is the same. We see something but how do we explain what we see in terms of what we’re used to talking about?”

In the case of Sailing Yacht Zero the information would also need to be useful for yacht crew who might not have racing experience, and are more interested in an efficient few hours of sailing so they can charge the batteries quickly before knocking off work.

The final challenge would be full automation, meaning the winches are connected to the data system and are continuously adjusting the sail trim at a rate and precision which humans could never achieve. Imagine algorithms which could consistently make tiny adjustments to sail tension as a yacht rises and falls with the swell - for repeatable and measurable results.

For now Bollweg’s report focuses on answering only the first of these three questions, which is to determine the feasibility of using LiDAR or photogrammetry to establish 3D sail shape in real time onboard Sailing Yacht Zero. Be sure to read the full report if you want all the details, the core ideas are discussed below.

LiDAR

LiDAR, or Light Detection and Ranging, operates by emitting millions of laser pulses per second and precisely measuring the time it takes for these pulses to reflect off an object and return to the sensor.

The main advantage of LiDAR lies in its ability to generate highly accurate and dense 3D point clouds. Even in challenging conditions like low light or rapid movement, LiDAR can still deliver precise geometric data. This makes it a strong contender for real-time sail shape detection, as the system can continuously scan the sails regardless of whether it's day or night, or if there are reflections that might hinder camera-based systems. But of course, it’s expensive, and that’s before even considering optimising the hardware for the harsh marine environment.

For a large yacht like Sailing Yacht Zero, one of the challenges is configuring the sensors to cover the full sail area. Bollweg proposes several potential layouts and setups which could work ranging from a single 360 degree sensor to multiple smaller sensors per sail which would then need to be synchronized before processing. All of this is possible with existing hardware.

One of the main problems with LiDAR though is that “you don't have the edge of the sail” explains Bollweg. “But If the point cloud is dense enough you can almost calculate the edge of the sail”. Because of the way the laser pulses work sharp, clear edges are typically difficult for LiDAR to render, and the edges of the sail are a common visual cue for sailors to read their sails in addition to the telltales themselves.

Photogrammetry

Photogrammetry relies on capturing multiple overlapping 2D images of an object from different angles to reconstruct a detailed 3D model. This method is particularly accessible and cost-effective because it leverages ordinary camera technology.

But unlike traditional photogrammetry where the object is static and the cameras are moved, on a yacht the cameras would remain fixed while the sail itself is in constant motion. Bollweg already bumped into this problem with their earlier experiments. “That was quite difficult because if you don't have an origin and a direction for all photos at the same time then it's difficult to see the differences and at that time we were really struggling with that… After 3 years of research in photogrammetry processing we can now solve this issue much better”

Some technologies already exist which make use of a single fixed camera and a fixed coloured stripe on a sail, often referred to as "speed stripes". These single-camera systems attempt to infer the 3D sail shape from a single image. But since a single image isn't enough for a real 3D measurement, these systems rely on assumptions, and attempt to guess the shape of the sail by how ‘curved’ the speedstripe is. While straightforward, this method’s primary limitation is lower accuracy due to the assumptions it has to make.

As with LiDAR the camera configuration is also a concern, but Bollweg proposes a number of options to enable all of the sail area to be covered onboard Sailing Yacht Zero with existing camera technology so this problem could also be overcome.

What’s next?

“I think that the 3D sail shape will be used in five or 10 years,” Bollweg states, “But then how will it be displayed? I'm not sure yet if it’s by numbers or by looking at shapes or you have a 3D shape on your screen and you look only from the back side?”

Bollweg thinks LiDAR is probably the better option for Zero, “I think it gives a lot more advantages than disadvantages and it's already used and the systems are small and you get 3D points.” But her report indicates that both technologies are up to the challenge depending on the use case.

If these ideas are played out will we one day see automated winches making continuous algorithmic microadjustments to an entire collection of sails onboard 300 m long cargo ships - all without a human “trimmer” in sight?

First we’ll need to see if Sailing Yacht Zero is able to build out a system to prove the viability of getting this delicate hardware and software to provide real value to actual sailors (and battery levels) over a long term operational period.